Terminus Group's Space Intelligent Building Product Upgrade: New Agent Function Added

Driven by the wave of intelligence, the construction industry is undergoing profound transformation. Recently, Terminus Group released an upgraded version of the OriginSYS AI Building Space Intelligent Control System—OriginSYS Ultra. Relying on AI technology innovation, it provides one-stop intelligent and efficient energy-saving solutions for emerging buildings such as smart computing centers.

Upgraded OriginSYS: Added Space Intelligence Feature

Terminus Group's OriginSYS is a building automation control system that analyzes the energy consumption data of various spaces and systems within a building. It uses AI algorithms to provide optimized control solutions and achieve precise energy usage predictions. Traditional building control systems are often plagued by poor compatibility and cumbersome management, making it challenging to meet the urgent needs for efficiency, energy-saving, and intelligence in modern buildings. The upgraded OriginSYS Ultra addresses these pain points by adding new features such as an AI assistant driven by spatial intelligence, full adaptation for industrial building automation, and intelligent operation and rapid configuration capabilities.

Spatial Intelligence AI Assistant

The AI assistant driven by spatial intelligence helps users quickly process data. Through the AI assistant, users can efficiently conduct data dialogues and statistical analyses. The system can also automatically generate customized reports according to needs, significantly enhancing data processing efficiency and accuracy. Supporting natural language interaction, the AI assistant allows users to obtain real-time data and analysis results via voice or text commands. This intelligent interaction method not only improves user experience but also provides a more convenient tool for building management.

Full Adaptation for Industrial Building Automation

OriginSYS Ultra achieves comprehensive adaptation to PLC controller systems, compatible with most PLC brands, and supports multiple communication protocols such as Snap7, EtherCAT, ADS, and Modbus. This upgrade enables the system to seamlessly connect with various industrial automation devices, expanding its applications in industrial buildings and intelligent manufacturing fields. By centrally processing alarms, trends, and schedules of various protocols on a unified platform, cross-system collaboration capabilities have been significantly enhanced, improving operational efficiency in industrial settings by about 25%.

Intelligent Operation and Rapid Configuration

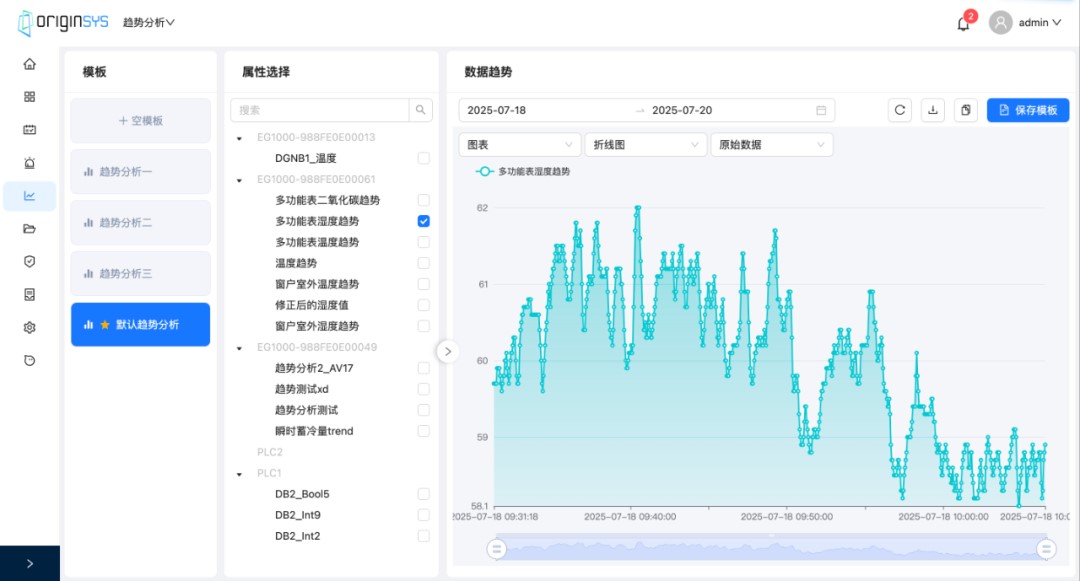

The system adds intelligent operation features such as trend hopping, allowing users to achieve complex data analysis and equipment control through simple operations. The rapid configuration function supports users in quickly building visual interfaces to monitor equipment operating statuses in real-time. Through these intelligent operations, OriginSYS Ultra not only improves system usability but also provides a more intuitive operational experience.

Four Major Functions to Aid Intelligent Building Upgrades

The upgraded OriginSYS Ultra features four core functions: comprehensive automation monitoring, spatial intelligent control and energy-saving optimization, cloud-edge-end collaborative distribution, and rapid all-in-one delivery. This system has been successfully applied in several landmark buildings.

In a research institute in Shanghai, based on OriginSYS Ultra and a series of intelligent terminal products, the institution's HVAC and lighting systems have been fully optimized, reducing daily energy consumption by about 15%. Through intelligent aggregation and demand-side response (DSR) mechanisms, the system can dynamically adjust loads during grid peak periods, participating in grid peak shaving and valley filling, thus maximizing energy utilization efficiency and earning potential incentives. The automated monitoring and management of mechanical and electrical equipment effectively reduce manual intervention, improving management efficiency by about 20%. The system uniformly coordinates various energy systems within the building, responds to virtual power plant dispatch instructions, and in conjunction with Terminus Group's comfort energy-saving model, intelligently adjusts environmental parameters to ensure indoor comfort.

In a large data center in Guangzhou, after applying OriginSYS Ultra, the energy consumption of the cooling source system dropped by about 25% compared to manual mode, with equipment efficiency significantly improved—PUE value reduced to 1.28, failure rate decreased by approximately 10%, and operational efficiency increased by about 30%. The stability of the production environment has significantly enhanced; the system can automatically adjust cooling conditions as required and monitor cold storage devices in real-time, achieving second-level switching in emergencies to ensure stable data center operations. The intelligent operation interface simplifies data analysis and equipment control processes, improving management efficiency by more than 20%.